Craft foaming process operation

The manual foaming process refers to the process in which the temperature-controlled materials are added to the mixing barrel of the manual foaming machine according to the quantity required by the formula, which are fully stirred and poured into the foaming foam in a certain shape in time in the moji-owning model. The whole process can be divided into three steps: preparing and weighing materials, feeding and stirring, and drying and molding.

The material according to material

All kinds of materials are controlled to 18 to 20℃ by heat preservation, and all kinds of materials are accurately weighed for use according to the requirements of the formula. In order to prevent the material temperature from being affected by the temperature, all materials should not be weighed too long in advance and should be weighed within 2-3 minutes before foaming.

Charging mixing

Feeding sequence is the most important step in the foaming process and must be operated strictly. The correct feeding order is:

PPG--L -- 580--T -- 9A -- 33, water ~ alkyl amine ~TDI

The operation method of feeding is as follows:

First mix the main ingredient PPG pour into the foaming machine barrel, stir gently (300 A 500 r/min), stirring edge, in turn, to join A 580 L, T A 9, 33, A water and alkyl amine five kinds of sauce, stir evenly mixed stop, the mixing speed is set in 900 - A - 1500 revolutions per minute (depending on how much foam material), mix TDI fast into the barrel, rapid mixing motor starting, TDI and other materials high-speed stirring 2 A 5 seconds later, immediately into the model, began to foaming material. Whether a good formula can foam into high-quality foam cotton, the key is to control the mixing time and speed of TDI after pouring. Stirring time is too long or stirring speed. Too fast, bubble cotton stomata disorder, large holes more, internal may have small cracks; Stirring time is too short or stirring speed is too slow, all kinds of material mix is not enough, make bubble cotton is foamed produce air bad, stoma is rough, may produce shrinkage, quality drops obviously. Under normal circumstances, the whole feeding process should be completed within 1--2 minutes, add small materials should be slowly stirring, in order to stir the tank material liquid level to form a small vortex without a large roll or splash. When TDI is added, it should be stirred instantly at high speed and the stirring time should be 2 to 4 times.

Drying out of the mold

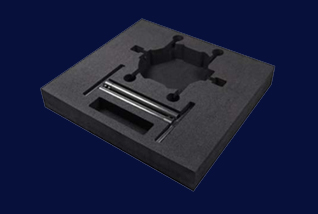

When the material is poured into the mold, it begins to foam. The material thickens rapidly from liquid to solid foam, and the volume expands continuously. When it rises to a certain height, the air is released (the gas is emitted). The height drops slightly, and the foaming ends. When the foam is over, let it dry in the mold for 3 to 4 minutes before the mold is ready to form. At this time, the foam is still soft and will stick to the hands. It needs to be dried and cured for 6 to 8 hours before further slicing.

- Analysis of processing technology of pearl foam profiled piece

- Analysis of packing performance and cost of foam material

- Safety analysis of pearl foam production

- Shanghai foam cotton foam production process

- You can save a lot of money on your electricity bills a year by keeping

- Shanghai pearl cotton manufacturer told how to distinguish the quality of pearl

- Shanghai bubble cotton factory to take you to choose cost-effective pearl cotton

- Shanghai bubble cotton factory to teach you how to choose pearl cotton from stat

- What is the economic benefit of Shanghai EPE Pearl Cotton Factory?

- A brief analysis of the quality of Shanghai Pearl cotton factory color is not af

- Shanghai EPE Pearl cotton factory explained the production process and technolog

- Shanghai EPE Pearl cotton Factory analyzed the factors affecting the transparenc

- Which field is Shanghai EPE Pearl cotton mainly applicable to?

- Shanghai Pearl cotton factory provides methods to prevent the aging of pearl cot

Current Position:

Current Position: